Valio will phase out the use of natural gas in energy production at Riihimäki dairy plant with the help of energy partner Adven. Energy production in Riihimäki was converted to biofuels already before, and natural gas has been used for heating only in the coldest weather. Now the natural gas boilers are replaced by an electric boiler. Electricity produced with renewable energy helps Valio on its path towards carbon neutrality in the future.

Continuous electricity distribution for food factories is a must in order for the Finnish food supply to run without interruptions. Valio’s dairy plants are generally in operation all the time, as milk is delivered to the factories every day around the clock. That’s why uninterrupted electricity supply is a prerequisite for the operation of Valio’s factories.

“Natural gas has been in use in Riihimäki factories for a longer time with a small load, and in this kind of use, the efficiency of natural gas is poor. In addition, to Valio’s goal is to reset milk’s carbon footprint to zero by 2035. This means phasing out fossil fuels such as natural gas “, says Peter Fabritius, Energy Manager at Valio.

Valio has two production plants in Riihimäki, a snack plant completed in 2017 and the Riihimäki dairy plant, which has been operating since the late 1960s, and was previously known as Herajoki dairy. The Riihimäki plant produces milk, buttermilk and cream. The new snack factory produces yogurt for domestic use and for export as well as plant based Oddlygood® goods.

At Riihimäki, electricity is needed in operating the equipment and in cooling the milk. Heat is needed, for example, in the heat treatment of the fresh products, in washing and in heating the properties.

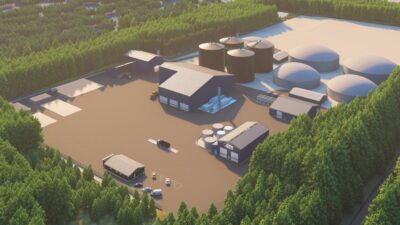

Adven has been producing energy as a service for Valio in Riihimäki since 2003. The biofuel plant, located at the plant area, was commissioned by Adven in 2009. The efficiency of a new electric boiler is much higher than the efficiency of the old natural gas boilers. The electric boiler will use carbon-neutral electricity in the future, which helps to further reduce carbon dioxide emissions by c. 1700 tons per year.

“In food production, security of energy supply is very important. Supplementing the current steam boilers with an electric boiler is an energy-efficient and reliable solution for Valio’s production”, says Jussi Hirvonen, Adven’s Key Account Manager.

Adven is Valio’s long-term partner and provides energy services at Valio’s production facilities all over Finland.